Our Production

Produce Line

The production process of rubber conveyor belts mainly includes: Mix rubber ingredients, Calender rubber onto carcass or create cover sheets, Build the belt (layering), Cut to size, Vulcanize (cure) under heat/pressure to form the final belt.

The equipment involved in the production of rubber conveyor belts mainly includes: Rubber mixing mills, Calenders, Building machines, Vulcanizing presses, etc.

Advanced production equipment and meticulous production operations are essential guarantees for product quality.

Rubber conveyor belt mixing is the critical first step of creating the rubber compound, blending natural rubber with fillers like carbon black and plasticizers, curatives, anti-aging agents in precise, controlled sequences within specialized mixers to achieve the specific properties needed for the final belt, such as wear resistance, oil resistance, fire resistance.

Our unique conveyor belt mixing formula from our Chinese factory ensures consistent performance in every batch of products.

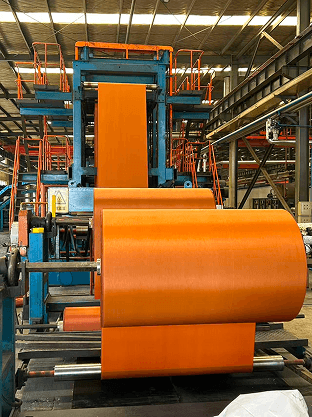

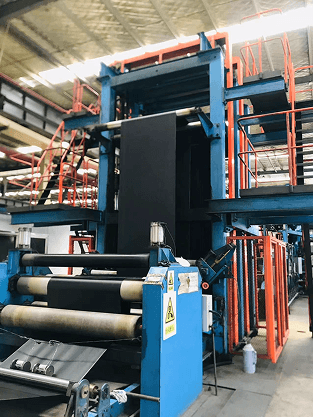

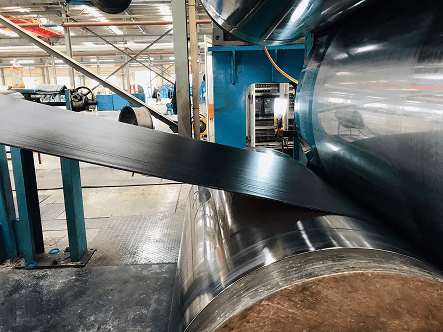

Rubber conveyor belt calendering is a key manufacturing step, The rubber compound is rolled into thin, consistent sheets, embedding fabric plies or steel cords within them, providing strength and dimensional stability for conveyor belts.

Our machines have four rolls, with advanced features like preloading and cross-axis adjustment for high precision. Rollers are temperature-controlled and precisely adjustable to manage rubber's stickiness and hardness, to create consistent, high-quality rubber sheets and coatings.

Forming machine: Layers the rubber, carcass, and cover rubber precisely, often with pulling/pushing devices for tension.

Rubber conveyor belt hot vulcanization is a crucial process. Layers the rubber, carcass, and fabric/steel cords through mixing, compounding, and calendaring, followed by assembly, cured in a press for a specific time, cooled, ad finally the process is completed.

Our production workshop has 21 curing presses and 2 roto cures with the widest conveyor belt vulcanization width reaching 2200mm.

Venting before vulcanization is an essential step to ensure that the rubber cover surface of the conveyor belt is smooth and flat after vulcanization, without the formation of rubber bubbles.

The molded edge process of rubber conveyor belts provides excellent protection against moisture, impact, and abrasion for the fabric carcass, ideal choice for harsh environments.

The cut edge process allows for very flexible widths from large slabs. It is suitable for use in relatively dry and clean environments.

Specialized equipment systems for producing steel cord conveyor belts include steel cord winding and tensioning devices, large -scale vulcanizing autoclaves, and cutting machine, creating powerful conveying systems for long-distance, heavy-duty material transportation in mining, ports, and power plants.